Bad Battery? There Might Be More To It

May 12, 2025

Read More

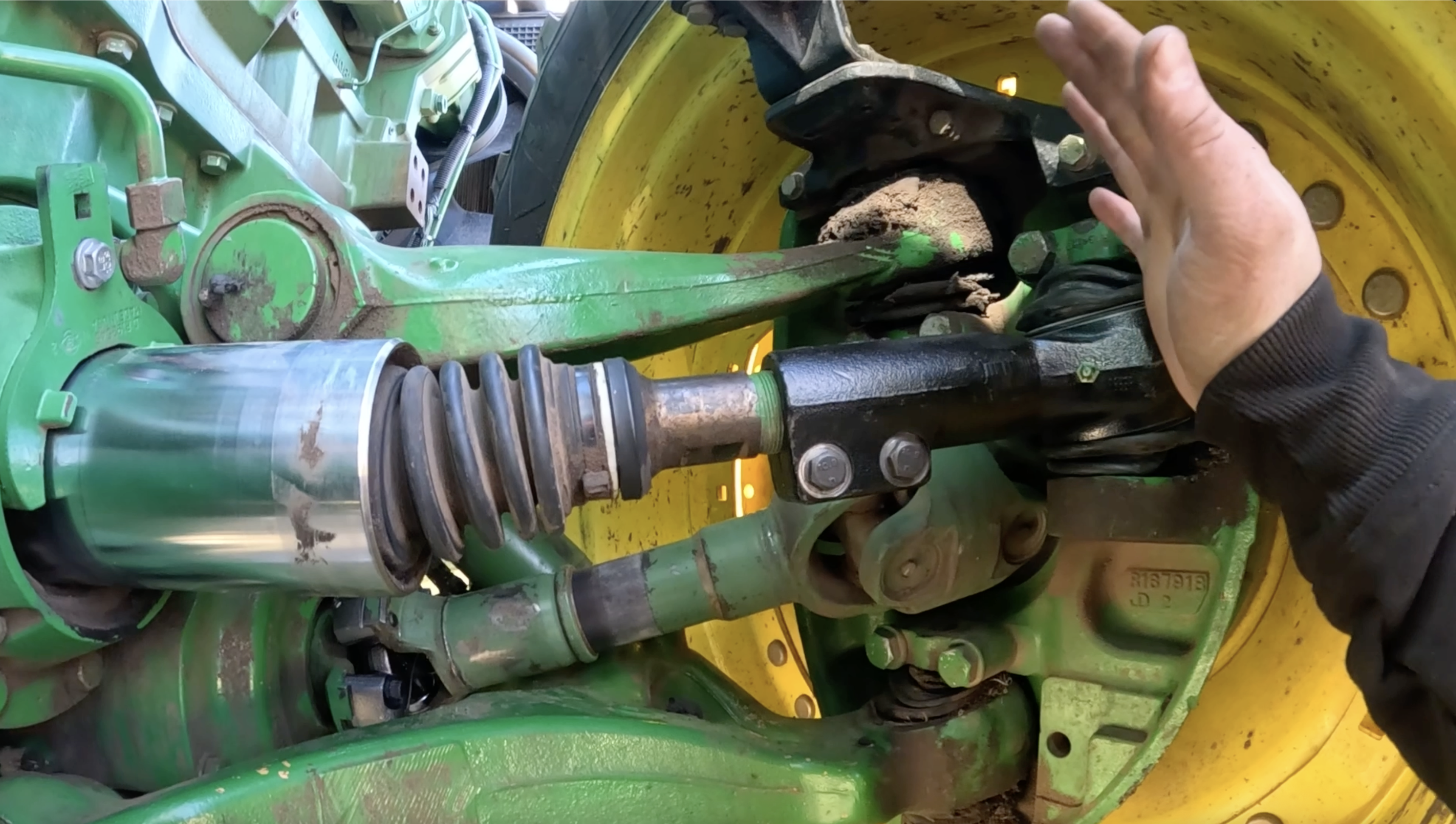

Start by removing the two bolts securing the steering arm's outer tie rod. Once those bolts are out, pivot the tie rod forward and pop it free from its housing.

Tip:

If your front tires are off the ground, they’ll want to fold back once the tie rod is loose. Try using a come-along to keep the tire steady and avoid pivoting unexpectedly.

Before you spin off the old tie rod, it’s crucial to measure the distance from the shoulder of the outer tie rod to the lip of the inner tie rod. This measurement ensures you reinstall the new tie rod at the correct length to maintain proper steering alignment.

With the tie rod disconnected:

Use a 19mm wrench to loosen the locknut.

Hold the inner tie rod steady with a pipe wrench while you spin the outer tie rod off.

Depending on how tight it is, you might need some heat to help break it loose.

Thread the new outer tie rod back onto the inner rod, matching the measurement you took earlier. The new bolts on this replacement part were

18mm instead of the original 19mm, so keep that in mind during reassembly.

Tap the dust cap back onto the new tie rod if it was removed.

Set the tie rod into its housing and pivot it into place.

Tip: Sometimes, you might need to be aggressive to get the tie rod fully seated into the housing.

Reinstall the two bolts and tighten them securely.

After installation, don’t forget to grease the new ball joint thoroughly. This step is crucial for longevity.

While the boot may look a bit twisted with the suspension fully extended, it will settle into the correct shape once the tractor is back on the ground.

A damaged or worn tie rod boot allows dirt and debris to enter the ball joint. Over time, that dirt mixes with grease and causes accelerated wear, leading to looseness and poor steering control. Keeping tie rod boots intact and joints properly greased will help extend the life of your steering components and keep your John Deere running like it should.

Replacing the outer tie rod on a John Deere Tractor isn’t complicated, but attention to detail makes all the difference. Proper measurements, clean parts, and fresh grease ensure your repair lasts and keeps your tractor operating safely in the field.

Compare {{items.length}}/4

Compare {{items.length}}/4